Department of Textile Engineering

Chairman's Message

Textile Engineering stands at the crossroads of tradition and innovation, blending centuries-old techniques with cutting-edge technology to create products that shape our everyday lives. Bangladesh's Readymade Garment (RMG) industry has been pivotal in driving economic growth and development. Its significance lies in its contribution to export revenue and its role as a major employer. As a member of the textile community, it gives me immense pleasure to share that Bangladesh’s readymade garment export procured $46.99 billion during the fiscal year 2022-23, which is 84.59% of total export earnings, recording a growth of 10.27% from the previous year.

At the Department of Textile Engineering of Uttara University, we take pride in nurturing the next generation of textile engineers who will drive this dynamic industry forward. Our curriculum is designed to provide a complete understanding of textile materials, processes, and applications while emphasizing sustainability, innovation, and global perspectives. Through hands-on laboratory experiences, industry internships, and research opportunities, our students gain the knowledge and skills needed to excel in a rapidly evolving industry.

The department offers a comprehensive educational journey supported by cutting-edge labs and a faculty of committed members with extensive academic and industry backgrounds. Our dedicated faculty members are experts in their fields and are committed to providing a supportive learning environment where students can thrive academically and professionally. They bring a wealth of industry experience and academic expertise to the classroom, ensuring that our students receive a well-rounded education that prepares them for successful careers in textile engineering and related fields. Furthermore, our department maintains strong partnerships with industry leaders and research institutions, enabling us to stay at the forefront of technological advancements and industry trends. These collaborations provide our students with valuable opportunities for networking, professional development, and real-world application of their skills. I am confident that our department will significantly contribute to enhancing textile education in Bangladesh.

As a proud member of this esteemed department, I invite everyone to explore our website and visit our campus to learn more about the exciting opportunities available at the Department of Textile Engineering, Uttara University. Together, let us embark on a journey of discovery, innovation, and excellence in textile engineering.

Dr Syed Rashedul Islam

Assistant Professor and Chairman

Department of Textile Engineering

Department Overview

The Department of Textile Engineering at Uttara University offers a comprehensive B.Sc. in Textile Engineering, a 4-year undergraduate program for students with a science background who have completed 12 years of education or hold a textile diploma. Enrollment is merit-based through a competitive admission test, welcoming students regardless of race, color, nationality, religion, or sex. The program features a blend of theoretical and practical courses, encompassing basic sciences and various engineering disciplines such as mechanical, electrical, production and industrial engineering, and computer sciences, alongside core textile engineering courses.

The curriculum also includes courses in the Bengali Language and Literature, Bangladesh Studies, and the History of the Emergence of Bangladesh, ensuring that graduates are well-prepared to serve and integrate into society. Emphasizing sustainability, the program educates students on the environmental and societal impacts of textile processes, promoting sustainable practices in their professional lives. Seven well-equipped labs support the practical aspects of the coursework, and students gain real-world experience through multiple visits to textile mills during their studies. An eight-week industrial training component bridges the gap between theoretical knowledge and practical application. Additionally, a project work component introduces students to textile research, facilitating opportunities for higher studies abroad. The program is instructed in English, with an English course in the first year to enhance graduates' global communication skills.

Textile engineering applies scientific principles to the manufacturing and development of various fabrics, aiming to design and control all aspects of textiles, from raw materials to finished products. The readymade garments industry, a cornerstone of Bangladesh's economy, has seen remarkable success over the past two decades, becoming a multi-billion-dollar export sector that accounts for 81% of the country's total export earnings.

To meet the industry's demand for highly skilled professionals with technological and managerial expertise, the department has dedicated and experienced faculty members with global exposure. The program aims to develop graduates who are creative, adaptable problem-solvers capable of taking on responsibilities in management, R&D, and competitiveness, using current engineering tools to design innovative textiles and processes. The department continues to strengthen its reputation as a center of excellence in scientific research and technological advancement.

Vision

To emerge as a leading department in providing state-of-the-art knowledge in various areas of textiles and conducting top-class research to explore different aspects of textile engineering.

Mission

- Prepare technically sound and qualified undergraduates for serving the textile industry.

- Ensure innovative educational practices and multi-disciplinary research activities.

- Provide visionary leadership and collaborative services to society as well as the textile industry.

- Create a problem-solving mindset for the graduates that will assist their professional life.

- Provide an effective educational foundation that will facilitate in pursuit of higher studies.

What Experties Do We Build Up?

After completion of the BSc in Textile Engineering Program, the graduates will:

- Be able to apply obtained technical knowledge in their professional life.

- Be able to contribute to the development of the textile industry, both nationally and globally.

- Grow communication, team building, and leadership skills to sustain in a competitive work environment.

- Conduct research activities that will enhance their intellectual capabilities in various dimensions of textile engineering.

- Carry out the responsibilities bestowed upon them with a positive frame of mind.

- Develop problem-solving skills related to their day-to-day life.

- Be interested in Entrepreneurship and innovation skills.

Objectives of the Program

- To equip students with knowledge and technical competence in the textile engineering discipline that is in line with industrial requirements.

- To enhance graduates' communication and presentation skills, fostering strong leadership qualities.

- To develop the ability to solve real-life textile-based problems effectively and ethically, with a focus on sustainability.

- To instill a commitment to lifelong learning, ensuring students achieve successful careers.

Medium of Instruction

Uttara University offers all the courses of study primarily in English. Teachers provide instruction to students in the classroom in English. English is also widely used as a medium of communication among the faculties, students, and administrative officials.

Academic Programs

Undergraduate

1. BSc in Textile Engineering (BSc in TE) (Regular) 4 Years

2. BSc in Textile Engineering (BSc in TE) (Evening) 3 Years

Description of the Program

Bachelor of Science (Engg.) in Textile Engineering (BSc in TE)

The program offers courses grounded in a broad spectrum of disciplines, including mathematics, basic science, humanities, and related sciences and engineering, with concentrations/majors in (1) Yarn Manufacturing, (2) Fabric Manufacturing, (3) Wet Processing, and (4) Apparel Manufacturing. The Bachelor of Science in Textile Engineering is a 160-credit-hour program, including 6 credit hours for Industrial Training & Project Work. The program includes General Education Courses (19 courses & 47 credits), Elective Courses (9 courses & 19 credits), Core Courses (42 courses & 88 credits), and Capstone/Industrial Training/Project courses (2 courses & 6 credits). The minimum duration of the program is 4 (four) years.

The program also offers a degree for diploma-holding students with a 20-credit waiver to complete the Bachelor of Science in Textile Engineering. They must earn a minimum of 140 credit hours, including 6 credit hours for Industrial Training & Project Work. Some courses from the 4-year program are waived for these students, depending on their major and non-major courses undertaken during the diploma program, based on the recommendation of the course exemption committee.

Graduate Attributes

The graduate attributes referred to in this curriculum are divided into three groups:

- knowledge profile

- Range of Complex Engineering Problem Solving and

- Range of Complex Engineering Activities

These graduate attributes are presented in Table 1, Table 2, and Table 3 below.

Table 1: Knowledge Profile

| Attributes | |

|---|---|

| K1 | A systematic, theory-based understanding of the natural sciences applicable to the discipline. |

| K2 | Concept-based mathematics, statistics, and the formal aspects of Textile Sciences and Technologies to support analysis and troubleshooting applicable to the discipline. |

| K3 | A systematic, theory-based formulation of engineering fundamentals is required in the engineering discipline. |

| K4 | Engineering specialized knowledge that offers bodies of knowledge and theoretical frameworks for the engineering discipline's recognized practice areas: this knowledge is at the forefront of the field. |

| K5 | Knowledge that supports engineering design in a practice area |

| K6 | Understanding of engineering technology and practice in the engineering discipline's practice areas |

| K7 | Knowledge of engineering's place in society and awareness of problems with the discipline's engineering practice public safety, ethics, and the engineer's professional duty; the effects of engineering; and sustainability in the social, cultural, environmental, and economic spheres |

| K8 | Engagement with selected knowledge in the research literature of the discipline |

Table 2: Range of Complex Engineering Problem Solving

| Attribute | Complex Engineering Problems have characteristic P1 and some or all of P2 to P7 |

|---|---|

| Depth of knowledge required | P1 : Cannot be resolved without in-depth engineering knowledge at the level of one or more of K3, K4, K5, K6, or K8, which allows a fundamentals-based, first principles analytical Approach |

| Range of conflicting requirements | P2 : Involve wide-ranging or conflicting technical, engineering, and other issues |

| Depth of analysis required | P3 : Have no obvious solution and require abstract thinking, and originality in analysis to formulate suitable models |

| Familiarity of issues | P4 : Involve infrequently encountered issues |

| Extent of applicable codes | P5 : Are outside problems encompassed by standards and codes of practice for professional engineering |

| Extent of stakeholder involvement and conflicting requirements | P6 : Involve diverse groups of stakeholders with widely varying needs |

| Interdependence | P7 : Are high-level problems including many parts or sub-problems |

Table 3: Range of Complex Engineering Activities

| Attribute | Complex activities mean (engineering) activities or projects that have some or all of the following characteristics |

|---|---|

| Range of resources | A1 : Involve the use of diverse resources (and for this purpose resources include people, money, equipment, materials, information and technologies) |

| Level of interaction | A2 : Require resolution of significant problems arising from interactions between wide-ranging or conflicting technical, engineering or other issues |

| Innovation | A3 : Involve creative use of engineering principles and research-based knowledge in novel ways |

| Consequences for society and the environment | A4 : Have significant consequences in a range of contexts, characterized by difficulty of prediction and mitigation |

| Familiarity | A5 : Can extend beyond previous experiences by applying principles-based approaches |

Educational Objectives of the Program

Following the vision and mission of the department, the B.Sc. (Engg.) in Textile Engineering program has been designed to produce competent graduates who will establish themselves as successful professionals or entrepreneurs within a few years after graduation. The program involves the following educational objectives. The graduates of this program shall be able:

PEO1: To apply technical knowledge acquired academically in line with industrial requirements.

PEO2: To communicate effectively and demonstrate strong leadership qualities in the workplace.

PEO3: To develop real-life problem-solving capabilities, applying them effectively and ethically through a sustainable approach.

PEO4: To become lifelong learners by developing entrepreneurial skills for successful career advancement.

Program Learning Outcomes

Program learning outcomes are the skills and competencies that students should be able to articulate, apply, or utilize (theoretically or practically) after completing their degree. Upon graduation, a student of Textile Engineering will gain the following abilities:

PLO1: Engineering Knowledge

Apply knowledge of mathematics, natural science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

PLO2: Problem Analysis

Identify, formulate, research literature, and analyze complex engineering problems, reaching substantiated conclusions using first principles of mathematics, natural sciences, and Textile engineering and sciences.

PLO3: Design/development of solutions

Provide solutions for difficult technical challenges and create systems, parts, or procedures that satisfy requirements while taking public health and safety, cultural, socioeconomic, and environmental factors into account.

PLO4: Investigations

Conduct investigations of complex textile engineering problems using research-based knowledge and advanced research methods, including the design of experiments, comprehensive data analysis, and synthesis of information, to provide valid and actionable conclusions.

PLO5: Modern Tool Usage

Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools, including prediction and modelling, to complex engineering problems, with an understanding of the limitations.

PLO6: The Engineer and Society

Apply reasoning informed by contextual knowledge to assess societal, health, safety, legal, and cultural issues, as well as the consequent responsibilities relevant to professional engineering practice and solutions to complex engineering problems.

PLO7: Environment and Sustainability

Understand and evaluate the sustainability and impact of professional Textile engineering work in the solution of complex engineering problems (EP1 to EP7) in societal and environmental contexts. (K7)

PLO8: Ethics

Apply ethical principles and commit to professional ethics and responsibilities, and norms of Textile engineering practice. (K7)

PLO9: Individual Work and Teamwork

Function effectively as an individual and as a member or leader in diverse teams and in multi-disciplinary settings.

PLO10: Communication

Communicate effectively on complex engineering activities with the engineering community and with society at large, such as being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

PLO11: Project Management and Finance

Demonstrate knowledge and understanding of engineering management principles and economic decision-making and apply these to one’s work as a member and leader in a team to manage projects and in multidisciplinary environments.

PLO12: Life-Long Learning

Recognize the need for and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

Mapping of PEOs with the Mission of the Department

| Program Educational Objectives (PEOs) | Mission of the Program Offering Entity | ||||

| Mission A | Mission B | Mission C | Mission D | Mission E | |

| PEO 1 | √ | √ | √ | ||

| PEO 2 | √ | √ | |||

| PEO 3 | √ | √ | |||

| PEO 4 | √ | √ | √ | ||

Mapping of PLOs with the PEOs

| PLOs | PEO 1 | PEO 2 | PEO 3 | PEO 4 |

|---|---|---|---|---|

| PLO 1 | ✔ | |||

| PLO 2 | ✔ | |||

| PLO 3 | ✔ | |||

| PLO 4 | ✔ | |||

| PLO 5 | ✔ | ✔ | ||

| PLO 6 | ✔ | ✔ | ||

| PLO 7 | ✔ | ✔ | ||

| PLO 8 | ✔ | ✔ | ||

| PLO 9 | ✔ | |||

| PLO 10 | ✔ | |||

| PLO 11 | ✔ | |||

| PLO 12 | ✔ |

Mapping courses with the PLOs

| Title | Details |

|---|---|

| Mapping courses with the PLOs | View |

Guideline For Student

Marks Distribution

| Particulars | Marks |

|---|---|

| Class Attendance + Class Performance | 5% |

| Class Test + Assignment | 10% |

| Mid Term Examination | 25% |

| Semester Final Examination | 50% |

| Viva Voce | 10% |

| Total | 100% |

Admission Requirements (Undergraduate)

Structure of the Curriculum

Duration of the Program

Years: 4 (Four)

Semesters: 8 (Eight)

Admission Requirements

Students obtaining a minimum CGPA of 2.5 or a second division in S.S.C and H.S.C can apply to the program. O-level and A-level students must have an average grade of ‘B’. Any further circulars from UGC will be updated in the system.

Students with diploma degrees are also eligible to apply.

Admission tests will be required for undergraduate programs. The written admission tests for the undergraduate program will be held in the following four areas:

- English

- Mathematics

- Physics and

- Chemistry

A student with a minimum score of 1200 (with a minimum of 400 in verbal) on the SAT may be exempt from taking the Bachelor program admission test (written) administered by the University. However, all students must attend a personal interview as part of the admission requirements. Candidates will be selected for the interview based on their results in the admission test (written).

Minimum Credit Requirement

The credit hour requirement for students with an H.S.C in a science background or equivalent, or those who have completed A-levels, is at least 160.0 credit hours over four years or eight semesters to award the B.Sc. in Civil Engineering degree.

- 160 credits for HSC passed students.

- Minimum 140 credits for Diploma holders.

The following courses will be waived for diploma-holding students.

| SL NO. | Course Code | Course Title | Credit |

|---|---|---|---|

| 1 | GED 0531 1103 | Chemistry-I | 3.00 |

| 2 | GED 0531 1104 | Chemistry-I (Lab) | 1.00 |

| 3 | PHY 0533 1105 | Physics-I | 3.00 |

| 4 | PHY 0533 1106 | Physics-I (Lab) | 1.00 |

| 5 | MAT 0541 1108 | Mathematics-I | 3.00 |

| 6 | TXE 0723 1205 | Textile Raw Material-I | 3.00 |

| 7 | TXE 0723 1102 | Introduction to Engineering Drawing | 1.00 |

| 8 | TXE 0723 2106 | Engineering Materials | 2.00 |

| 9 | BUS 0411 3210 | Principles of Accounting and Marketing | 3.00 |

| Total Credit | 20.00 | ||

Total Class Weeks in a Semester

28 Weeks in a Year / 14 Weeks in a Semester

Minimum CGPA Requirements for Graduation

2.00 out of 4.00

Maximum Academic Years of Completion

7 years (Program duration 4 years + Registration validation 3 years)

Category of Courses

| Category | Credit hours |

|---|---|

| General Education Courses | 47 |

| Elective Courses | 19 |

| Core courses. | 88 |

| Capstone/Industrial Training/Projects | 06 |

| 160 |

General Education Courses

| SL No. | Subject | Credit |

|---|---|---|

| 1 | Mathematics - 1 | 3 |

| 2 | Chemistry - 1 | 3 |

| 3 | Chemistry 1 (Lab) | 1 |

| 4 | Physics - I | 3 |

| 5 | Physics - I (Lab) | 1 |

| 6 | Statistics | 3 |

| 7 | Mathematics - II | 3 |

| 8 | Physics - II | 3 |

| 9 | Physics - II (Lab) | 1 |

| 10 | Chemistry - II | 3 |

| 11 | Chemistry - II (Lab) | 1 |

| 12 | English Language | 3 |

| 13 | Principles of Accounting & Marketing | 3 |

| 14 | Bengali Language and Literature | 3 |

| 15 | History of Emergence of Bangladesh | 3 |

| 16 | Fundamentals of Computer and Programming | 3 |

| 17 | Fundamentals of Computer and Programming (Lab) | 1 |

| 18 | Bangladesh Studies | 3 |

| 19 | Research Methodology | 3 |

| Subtotal = 19 | 47 | |

Elective Course

| SL No. | Subject | Credit |

|---|---|---|

| 20 | Environment and Pollution Control | 2 |

| 21 | Industrial Engineering | 3 |

| 22 | Industrial Management | 3 |

| 23 | Introduction to Polymer Science | 3 |

| 24 | Workshop Practice | 1 |

| 25 | Elements of Electrical and Electronics Engineering | 3 |

| 26 | Elements of Electrical and Electronics Engineering (Lab) | 1 |

| 27 | Elements of Mechanical Engineering and Machine Design | 3 |

| 28 | Elements of Mechanical Engineering and Machine Design (Lab) | 1 |

| 29 | Mechatronics and Automatic Control Engineering | 2 |

| Subtotal = 10 | 22 | |

| 9 courses & 19 credits will be offered from the Elective Course | ||

Core Courses

| SL No. | Subject | Credit |

|---|---|---|

| 30 | Introduction to Textile Engineering | 3 |

| 31 | Introduction to Engineering Drawing | 1 |

| 32 | Engineering Materials | 2 |

| 33 | Textile Raw Material-I | 3 |

| 34 | Yarn Manufacturing –I | 3 |

| 35 | Yarn Manufacturing –I (Lab) | 1 |

| 36 | Fabric Manufacturing –I | 3 |

| 37 | Fabric Manufacturing -I (Lab) | 1 |

| 38 | Wet Processing –I | 3 |

| 39 | Wet Processing -I (Lab) | 1 |

| 40 | Apparel Manufacturing –I | 3 |

| 41 | Apparel Manufacturing –I (Lab) | 1 |

| 42 | Textile Raw Material –II | 3 |

| 43 | Yarn Manufacturing –II | 3 |

| 44 | Yarn Manufacturing –II (Lab) | 1 |

| 45 | Fabric Manufacturing –II | 3 |

| 46 | Fabric Manufacturing -II (Lab) | 1 |

| 47 | Wet Processing –II | 3 |

| 48 | Wet Processing -II (Lab) | 1 |

| 49 | Apparel Manufacturing –II | 3 |

| 50 | Apparel Manufacturing –II (Lab) | 1 |

| 51 | Textile Testing and Quality Control-I | 3 |

| 52 | Textile Testing and Quality Control-I (Lab) | 1 |

| 53 | Textile Testing and Quality Control-II | 3 |

| 54 | Textile Testing and Quality Control-II (Lab) | 1 |

| 55 | Textile Testing and Quality Control-III | 3 |

| 56 | Textile Testing and Quality Control-III (Lab) | 1 |

| 57 | Textile Physics | 3 |

| 58 | Fabric Structure and Design | 3 |

| 59 | Fabric Structure and Design (Lab) | 1 |

| 60 | Fashion Design and Technology | 3 |

| 61 | Fashion Design and Technology (Lab) | 1 |

| 62 | Application of Computer in Textiles | 2 |

| 63 | Apparel Merchandising and International Trade | 3 |

| 64 | Technical Textile | 3 |

| 65 | Yarn Manufacturing –III | 3 |

| Fabric Manufacturing –III | ||

| Wet Processing –III | ||

| Apparel Manufacturing –III | ||

| 66 | Yarn Manufacturing –III (Lab) | 1 |

| Fabric Manufacturing –III (Lab) | ||

| Wet Processing –III (Lab) | ||

| Apparel Manufacturing –III (Lab) | ||

| 67 | Specialized Yarn Product | 2 |

| Specialized Fabric Product | ||

| Specialized Wet Processing | ||

| Specialized Garments Product | ||

| 68 | Maintenance and Management of Textile Machinery | 2 |

| 69 | Maintenance and Management of Textile Machinery (Lab) | 1 |

| 70 | Production Planning and Control | 3 |

| 71 | Comprehensive Viva Voce | 1 |

| Subtotal = 42 | 88 | |

Capstone/Industrial Training/Projects

| SL No. | Subject | Credit |

|---|---|---|

| 72 | Industrial Training | 3 |

| 73 | Project Work | 3 |

| Subtotal = 02 | 6 | |

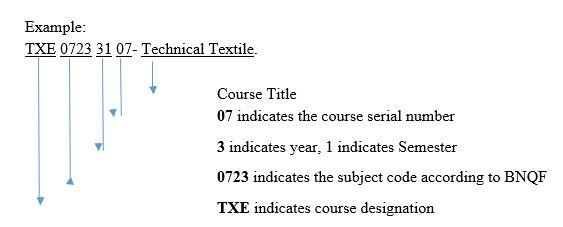

Course Designation and Numbering System

Each course is designated by a code that includes the following:

- All course numbers will have 8 (eight) digits.

- Departmental courses will begin with TXE followed by an 8-digit number.

- Mathematics-related courses will begin with MAT followed by an 8-digit number.

- English Language-related courses will begin with ENG followed by an 8-digit number.

- Physics-related courses will begin with PHY followed by 8-digit numbers.

- Computer Science and Engineering-related courses will begin with CSE followed by 8-digit numbers.

- Business-related courses will begin with BUS followed by 8-digit numbers.

- Bengali-related courses will begin with BAN followed by an 8-digit number.

- All other General courses will begin with GED followed by an 8-digit number.

- Description of digits:

- 1st four numeric digits- Subject code according to BNQF (detailed field)

- 5th digit- Year

- 6th digit- Semester

- 7th and 8th digit- Course number. (Note: odd numbers indicate theoretical course, and even numbers indicate lab course, except 411 indicates Project I and 422 indicates Project II.)

Year/Level/Semester/Term wise distribution of courses

| Title | Details |

|---|---|

| Semester wise distribution of courses | View |

Advisor and CR List

| Title | Details |

|---|---|

| List of Department Advisor and CR | View |

UU Textile Society

Textile Workshops

We host workshops where participants can pick up skills in dying, printing, weaving, and working with cloth.

Fashion Shows

The club organizes fashion shows where students can display their designs and get hands-on event planning experience.

Textile Art Exhibitions

We routinely host exhibitions to showcase our members' work and encourage them to experiment with textile art as a means of self-expression.

Guest Speakers

Professionals with a background in textile and fashion are welcome to speak with club members about their experiences and perspectives.

Sustainability Initiatives

We inform members about the value of eco-friendly fashion and advocate for sustainable methods in the textile industry. Students can check out books, articles, and other materials about textiles and fashion from our club's inventive textile library.

Departmental Committees

| Committee Name | Responsibilities | Convener | Members |

|---|---|---|---|

| Exam Committee (Evening) | Invigilation planning, Question collection and moderation, Question and answer script preparation, Seat planning, Script receiving and delivery, Retake course list collection and exam conducting, Conducting Exams and related work, Room managing for examination. | Md. Anwar Hossain | Tauqir Khan, Mahbub Morshed Khan, Md Hanif Munshi, Sharmin Sultana Mime, Nazmunnahar, Nabil Shahriar Dhrubo, Anamul Haque Eanam |

| Exam Committee (Regular) | Invigilation planning, Question collection and moderation, Question and answer script preparation, Seat planning, Script receiving and delivery, Retake course list collection and exam conducting, Conducting Exams and related work, Room managing for examination. | A T M Gulam Moula | Md. Mosfiqur Rahman, Kamrunnahar Happy, Nuruzzaman Nafiz, Habibur Rahman, Asifur Rahman, Md. Hasan Mia |

| Routine Committee | Class routine preparation, Exam Routine, Room Schedule | Md. Mosfiqur Rahman | Mahbub Morshed Khan, Md. Mehedi Hasan Modern |

| Admission Committee | Activities planning, Cost calculation, Flyer preparation, Communicating with institutions, Promotional visit planning, Visit monitoring, Lab visit conducted, Students motivation, Gifts arrangement, Transport management, Remuneration ensuring, Student admission monitoring, Database making, Connecting with the new institution and arranging visits. | Abdullah Al Rakib Shikder | Rijon Saha, Zihan Kaisar, Abdullah |

| Project & Intern Committee | Major subject selection, Group distribution (intern & project), Internship management, Supervisor distribution, Defense monitoring, Report collection, Bill preparation and submission, Result preparation | Abdullah Al Rakib Shikder | Mohammad Saiful Islam, Md. Hasan Mia, Nazmunnahar |

| Extra-Curricular Committee | Orientation program, Job fair arrangement, Training session, UU Textile Society and all other club management, Sports arrangement, Observing national events, Alumni and related work, Cultural program | A T M Gulam Moula | Kamrunnahar Happy, Nuruzzaman Nafiz, Md. Hasan Mia, Taukir Khan |

| Co-Curricular Committee | Industrial visit arrangement & conducting, Seminar for existing students, Workshop and seminar for students, Tour arrangement | Rijon Saha | Md. Saiful Islam, Mahbub Morshed Khan, Sharmin Sultana Mime |

| Research Cell | Workshop on research motivation, Research work monitoring, Publication, Collaboration | Abdullah Al Rakib Shikder | Rijon Saha, Md. Hasan Mia, Nuruzzaman Nafiz, Md. Hanif Munshi |

| Job Placement Committee | Arranging jobs for the students, Collecting the CV of the applicant, Contact with HR and officials of industries, Job fair, Market trend analysis and taking steps | Md. Anwar Hossain | Saiful Islam, Mahbub Morshed Khan, Zihan Kaisar |

| Class Monitoring Cell | Class monitoring, Timely class conduction, Reporting, Rescheduling, Penalty | Md. Anwar Hossain | Mahbub Morshed Khan, Anamul Haque Eanam, Nazmul Alam Raihan, Md. Shohanur Rahman, Md. Rasel Mia |

| Coordinator | Result collection, Result correction, Result approval and publication, Course load calculation, Enrollment issues, Attending meeting, Course offering, Faculty assigning, Enrollment issues, Bill calculation and arrangement, Solving students problems | Jabed Hossen Emon | Abdullah Al Rakib Shikder, Habibur Rahman, Zihan Kaiser |

Research Projects

Projects: In Progress or Ongoing

| Sl No. | Name of Research Project | Department | Name of Project Manager |

|---|---|---|---|

| 1 | Development of Electrically Conductive Textile Fabric by Coating with Conductive Cu/Ag-Based Compounds Using Sol-Gel Method | Textile Engineering | Mosfiqur Rahman Senior Lecturer, E-mail: mosfiqur@uttarauniversity.edu.bd, Cell: 01773-101533 |

| 2 | From Toxicity to Sustainability: A Green Approach to Enhance Flame Retardancy in Cotton Textiles Using Waste Coconut Shell and Lemon Extract | Textile Engineering | Abdullah Al Rakib Shikder Senior Lecturer, E-mail: terakib@uttarauniversity.edu.bd., Cell: 01918-253106 |

| 2 | Development of Jute Fiber Reinforced Biocomposites – Effect of Fillers | Textile Engineering | A.T.M. Gulam Moula Senior Lecturer, E-mail: gulammoula35@yahoo.com, Cell: 01710-506428 |

Research Areas

Md. Abu Bakar Diddiquee

- Wet Processing Engineering

- Garments Manufacturing Engineering

- Smart Textiles

- Environment

- Pollution Control

Md Humayun Kabir Khan

- Apparel

- Washing

- Special Apparel

Abdullah Al Rakib Shikder

- Finishing

- Nanotechnology

- Productivity Improvement

- Composite material

- Sustainable textile

Anwar Hossain

- Modern spinning

- Fancy yarn

- Innovation in spinning

- Process optimization in spinning

- Nano Textiles

- Medical Textile

- Clothing comfort

Mahbub Morshed Khan

- Composite materials

- Surface modification

- Denim washing

Jabed Hossen Emon

- Biobased Epoxy Resin (Thermosets Resin)

- Yarn Manufacturing

- Washing

- Antibacterial Finishes on Textile

Mosfiqur Rahman

- Thin Films

- Semiconductor Materials

- Nanomaterials

- Solar Cell

- First Principles Calculations

- Density Functional Theory

Abdullah

- Machine Learning

- Deep Learning

- Data Science

- IoT

Mohammad Saiful Islam

- Dyeing with natural dyes

- Technical Textiles

- Seam and stitch

- Garments washing

Zihan Kaisar

- Functional Materials

- Textile Fibres and Polymers

- Smart Textiles

- E-Textiles

Habibur Rahman

- Smart Textiles

- Machine development

- Technical Textiles

- Advanced Textiles Materials

Asifur Rahman

- Fabrication of nanomaterials

- Photocatalysis and pollutant removal

- Environmental and health risk assessment

- Electrochemistry

Tauqir Khan

- Computational Fluid Mechanics

- Thermal Energy

- Renewable Energy

Md. Hanif Munshi

- Biopolymers

- Nanoscience

- Waste management

- Pharmaceuticals

- Computational Studies

Rijon Saha

- Textile Finishing

- Nanotechnology

- Productivity Improvement

- Product Quality Management

- Clothing Comfort

Md. Nuruzzaman

- Nonlinear PDEs

- Soliton Theory

- Wave Propagation

- Fractional Derivative

- Bifurcation Analysis

Md. Mehedi Hasan Modern

- Computational Mathematics

- Modeling with ODEs and PDEs

- Numerical Methods

- Optimization

Anamul Haque Enam

- Computational Mathematics

- Modeling with ODEs and PDEs

- Numerical Methods

- Optimization

A.T.M Gulam Moula

- Surface Modification of Textiles

- Polymer Science

- Organic Polymer

- Dyes and Chemical

Resources

1. Project Work Template

| Title | Details |

|---|---|

| Project Work Template | View |

2. Industrial Report Template

| Title | Details |

|---|---|

| Industrial Report Template | View |

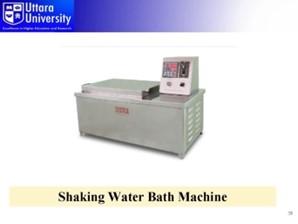

Lab Facilities

- Spinning Lab

- Fabric Manufacturing Lab

- Wet Processing Lab

- Apparel Manufacturing Lab

- Textile Testing and Quality Control Lab

- Workshop Lab

1. Spinning Lab

2. Fabric Manufacturing Lab

3. Wet Processing Lab

4. Apparel Manufacturing Lab

5. Textile Testing and Quality Control Lab

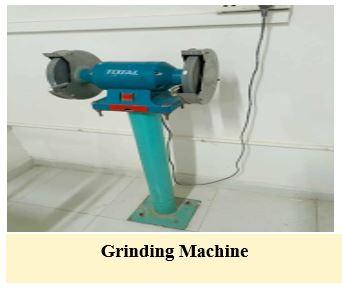

6. Workshop Lab

Please Enter

Your Personal Details

Staff of the Department of Textile Engineering

Md. Abdul Mannan

Senior Section Officer

MSc, National University

BSc, National University

View DetailsContact and Location

Visit Us : Holding 77, Beribadh Road, Turag, Uttara, Dhaka 1230, Bangladesh

Mobile : 01872607360-69

E-mail : info@uttarauniversity.edu.bd

Loading...